Pengantar

Menara saluran transmisi merupakan bagian vital dari sistem jaringan listrik kita, memungkinkan listrik mengalir melintasi jarak yang jauh. Struktur baja besar ini menopang kabel-kabel tegangan tinggi tebal yang membawa daya listrik dari stasiun pembangkit hingga ke gardu induk lokal sebelum mencapai daerah pemukiman dan bangunan komersial. Menghasilkan desain yang tepat untuk menara-menara ini membuat perbedaan besar dalam menjaga pasokan listrik tetap aman dan efisien. Rekayasa yang baik dalam konstruksi menara membantu mencegah terjadinya pemadaman saat badai atau cuaca ekstrem, sekaligus mengurangi risiko kegagalan listrik berbahaya yang dapat mengganggu layanan bagi ribuan orang sekaligus.

Apa itu Menara Saluran Transmisi ?

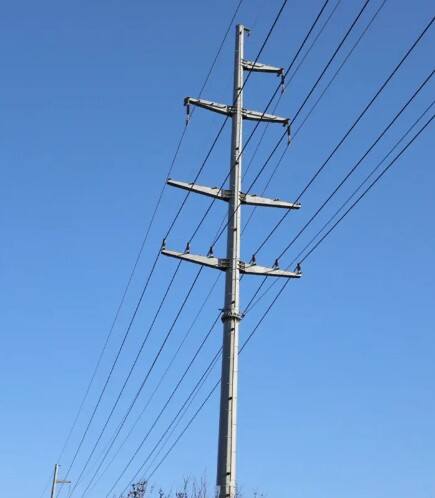

Menara transmisi memainkan peran penting dalam infrastruktur jaringan listrik kita, pada dasarnya berfungsi sebagai penopang raksasa bagi kabel listrik udara yang kita lihat membentang di sepanjang pemandangan. Sebagian besar struktur ini berbentuk rangka baja tinggi yang mengangkat kabel berarus tegangan tinggi jauh di atas permukaan tanah agar dapat beroperasi secara aman tanpa gangguan. Apa yang membuat menara-menara ini begitu penting? Nah, sebenarnya menara-menara ini dibangun menggunakan pengetahuan dari berbagai bidang teknik yang saling bekerja sama. Tanpa menara ini, menjaga aliran listrik secara andal sepanjang ratusan kilometer akan hampir mustahil. Bayangkan berapa banyak rumah tangga dan bisnis yang bergantung pada jaringan ini setiap hari.

Menara saluran transmisi sangat penting untuk mengalirkan listrik dari pembangkit listrik ke gardu induk lokal tempat listrik kemudian didistribusikan lebih lanjut. Struktur-struktur ini menjadi dasar sistem kelistrikan kita, memungkinkan arus listrik bergerak menempuh jarak jauh dengan sedikit kehilangan tenaga. Menara-menara ini menopang kabel-kabel tebal yang membawa seluruh daya yang kita andalkan setiap hari. Dukungan ini membuat seluruh jaringan listrik jauh lebih andal sehingga rumah tangga dan bisnis tetap mendapat pasokan stabil bahkan pada saat permintaan puncak. Dibangun untuk bertahan lama, menara-menara ini mampu menghadapi segala sesuatu mulai dari angin kencang hingga penumpukan es, yang menjelaskan mengapa mereka tetap berdiri tegak baik di pusat kota maupun di daerah pedesaan terpencil tempat akses ke listrik paling dibutuhkan oleh komunitas.

Yang membuat semua ini dimungkinkan adalah kerja cermat yang dilakukan dalam mendesain menara saluran transmisi. Para insinyur harus mempertimbangkan segala hal mulai dari pola cuaca setempat hingga seberapa besar beban yang dapat ditahan setiap menara sebelum mulai membengkok atau patah. Struktur-struktur ini muncul di mana-mana, baik di perkotaan yang padat bangunan maupun di daerah pedesaan yang terpencil sekalipun. Menara-menara ini memainkan peran besar dalam mendistribusikan tenaga listrik ke tempat-tempat di mana orang tinggal dan bekerja, memastikan lampu tetap menyala dan mesin terus berjalan di hampir seluruh planet saat ini. Keselamatan juga jelas menjadi penting, karena tidak ada yang menginginkan pemadaman listrik atau infrastruktur yang rusak akibat desain yang tidak tepat sejak awal.

Jenis-jenis Menara Saluran Transmisi

Desain menara saluran transmisi hadir dalam berbagai bentuk dan ukuran, masing-masing dibangun untuk peran tertentu dalam jaringan listrik kita. Ambil contoh menara rangka kisi-kisi, yang cukup populer berkat kemampuannya menyeimbangkan kekuatan struktural dengan penggunaan material yang relatif efisien. Kerangka menara ini tersusun dari bagian-bagian logam yang saling terhubung membentuk pola terbuka, yang sebenarnya sangat efektif menahan angin sekaligus memudahkan perawatan saat dibutuhkan. Kita sering melihatnya menjulang tinggi di pemandangan pedesaan dan di sepanjang jalur listrik besar yang membentang antar kota karena menara jenis ini menawarkan nilai ekonomis tanpa mengorbankan keandalan. Terutama penting di wilayah pegunungan atau daerah rawan badai, struktur ini mampu mendistribusikan tekanan secara efektif melalui kerangka-nya, yang membantu mencegah kegagalan saat terjadi kondisi cuaca ekstrem.

Menara tubular memiliki bentuk silinder yang rapi dan mampu memberikan kesan menarik sekaligus kuat pada saat bersamaan. Menara ini berbeda dengan menara rangka terbuka berbentuk kisi karena bentuknya yang padat di seluruh bagian. Konstruksi padat ini membantu menara ini bertahan lebih baik terhadap cuaca buruk dan menjaga kabel atau jalur yang terhubung lebih aman. Kota-kota cenderung memilih menara jenis ini ketika faktor penampilan menjadi penting karena menara ini secara visual tidak mencolok. Meskipun ukurannya lebih kecil, menara ini tetap memiliki daya tahan yang cukup besar sesuai fungsinya.

Menara monopole hanya memiliki satu tiang besar yang berdiri tegak, sementara itu menempati sedikit ruang di permukaan tanah. Hal ini membuatnya sangat cocok untuk kota-kota yang padat dengan bangunan dan penduduk. Desain yang kompak membantu menghemat lahan berharga, sebuah keuntungan besar saat memasang infrastruktur di tempat yang sempit. Banyak pemerintah daerah yang bahkan lebih memilih menara ini karena secara visual tidak mencolok dibandingkan opsi lainnya. Selain itu, menara ini sangat efektif digunakan untuk menarik jalur listrik di permukiman padat yang memang tidak memiliki cukup lahan terbuka. Perencana kota menganggap struktur ini sangat berguna untuk memperluas jaringan listrik tanpa harus merobohkan bangunan yang sudah ada atau mengganggu aktivitas sehari-hari di kawasan ramai.

Pertimbangan desain utama

Merancang menara saluran transmisi melibatkan beberapa elemen kunci yang menentukan seberapa baik menara tersebut bertahan seiring waktu. Kapasitas beban dan kekuatan struktural termasuk aspek yang paling penting. Menara-menara ini menghadapi berbagai macam gaya selama masa pakainya. Bayangkan beban konstan dari menara itu sendiri ditambah kabel-kabel yang tergantung di atasnya. Belum lagi gaya-gaya tak terduga seperti badai angin, aktivitas seismik, atau curah salju yang tinggi. Melewati ujian tekanan semacam ini membutuhkan perhitungan matematis yang cermat di balik layar. Banyak insinyur saat ini mengandalkan alat-alat canggih seperti perangkat lunak analisis elemen hingga untuk memodelkan apa yang terjadi ketika tekanan-tekanan berbeda mengenai struktur tersebut. Pendekatan ini membantu menemukan titik keseimbangan antara membangun struktur yang cukup aman sekaligus menjaga biaya konstruksi tetap masuk akal. Toh pada akhirnya, tidak ada yang ingin melihat jaringan listrik putus saat badai salju di musim dingin atau badai petir di musim panas.

Memilih bahan yang tepat sangat penting saat membangun menara transmisi karena keputusan ini memengaruhi seberapa lama menara tersebut bertahan dan seberapa baik fungsinya. Kebanyakan insinyur memilih antara baja atau aluminium untuk struktur ini. Baja selalu menjadi favorit karena kekuatannya yang cukup untuk menahan beban berat dan harganya umumnya lebih murah dibandingkan bahan lainnya. Aluminium juga bisa digunakan tetapi memiliki beberapa kekurangan. Benar bahwa aluminium lebih ringan dan tidak mudah berkarat, sehingga cocok digunakan di daerah pesisir di mana udara garam merusak logam, tetapi harganya jelas lebih mahal. Dalam memilih bahan tersebut, faktor-faktor seperti jenis beban yang harus ditopang menara, lokasi pemasangan, dan anggaran yang tersedia turut memengaruhi keputusan akhir. Memilih dengan tepat berarti menara tidak hanya terlihat bagus tetapi juga menjalankan tugasnya secara efektif selama masa pakainya tanpa memerlukan perbaikan atau penggantian terus-menerus.

Lingkungan memegang peran penting dalam merancang struktur. Kecepatan angin dan perubahan suhu harian sangat memengaruhi apakah menara dapat tetap berdiri tegak. Kondisi tanah di bawahnya juga berpengaruh karena jenis tanah berbeda di setiap wilayah, sehingga pondasi membutuhkan perlakuan khusus tergantung lokasi pembangunannya. Wilayah yang berisiko tinggi terhadap gempa bumi atau daerah rawan banjir memerlukan perhatian khusus dalam pekerjaan fondasi. Saat insinyur mempertimbangkan semua aspek lingkungan ini, mereka dapat membangun menara yang sesuai dengan lokasinya. Keselamatan menjadi prioritas utama sambil tetap memastikan operasional berjalan lancar. Tujuan utama dari perencanaan yang terperinci ini adalah mengurangi masalah sebelum terjadi dan menjaga jaringan listrik tetap berfungsi secara andal meskipun menghadapi kondisi cuaca yang ekstrem.

Komponen struktural dari Menara saluran transmisi

Stabilitas menara saluran transmisi sepenuhnya bergantung pada konstruksi dasar dan pekerjaan fondasinya. Tanpa dukungan yang memadai, struktur besar ini tidak akan mampu menahan beban angin atau tegangan lainnya yang mereka alami setiap hari. Fondasi juga memiliki fungsi ganda dengan cara menyebarluaskan berat menara ke seluruh permukaan tanah sambil tetap bertahan terhadap tekanan alam yang terus-menerus. Kebanyakan insinyur memilih antara pondasi tiang beton atau pondasi tiang pancang tergantung pada kondisi lapangan. Saat memasang fondasi ini, tim pemasangan perlu menggali cukup dalam melalui lapisan-lapisan tanah dan juga mempertimbangkan pola cuaca setempat. Memperhitungkan dimensi dengan tepat sangatlah penting karena tidak ada yang ingin melihat menara miring seperti Menara Pisa, apalagi sampai roboh total saat badai.

Kaki penopang menara sangat penting untuk mendistribusikan beban secara merata ke seluruh struktur agar tidak ada titik yang mengalami kelebihan beban. Menara yang berbeda membutuhkan jenis kaki yang berbeda tergantung pada ketinggiannya dan kondisi yang dihadapi sehari-hari. Sebagai contoh, menara komunikasi yang lebih pendek mungkin memiliki penopang segitiga sederhana, sedangkan menara yang lebih tinggi memerlukan konfigurasi yang lebih kompleks. Yang terpenting adalah kaki tersebut dibangun cukup kuat untuk menjaga stabilitas ketika menghadapi tantangan nyata seperti tiupan angin kencang dari samping atau penumpukan salju yang berat seiring waktu. Tanpa penguatan yang memadai di area kritis ini, bahkan titik tekanan kecil sekalipun dapat menyebabkan masalah yang lebih besar di masa mendatang.

Crossarms yang terpasang pada menara transmisi memainkan peran penting dengan menjaga posisi kabel listrik secara tepat. Penopang horizontal ini mempertahankan jarak aman antara kabel listrik agar tidak secara tidak sengaja bersentuhan dan menyebabkan korsleting berbahaya. Isolator bekerja bersama-sama dengan crossarms juga demi alasan keamanan. Terbuat dari bahan porselen atau komposit, perangkat isolasi ini mencegah aliran listrik turun melalui struktur menara logam, yang dapat menyebabkan kondisi gangguan serius. Ketika crossarms dan isolator berfungsi dengan baik, seluruh sistem dapat secara andal mengalirkan arus tegangan tinggi sepanjang ratusan mil tanpa membahayakan komunitas di sekitarnya atau merusak peralatan yang ada di sepanjang jalur transmisi.

Proses Desain dan Prinsip Teknik

Dalam mendesain menara saluran transmisi, langkah pertama biasanya disebut sebagai tahap desain dan analisis awal. Pada tahap ini, para insinyur melakukan berbagai pemeriksaan dan perhitungan untuk mengevaluasi apakah proyek tersebut benar-benar dapat direalisasikan dalam praktiknya. Mereka mempertimbangkan hal-hal seperti bagaimana menara mungkin mempengaruhi habitat satwa liar setempat, kondisi tanah di lokasi yang dipertimbangkan, serta apakah semua persyaratan dokumen dari instansi pemerintah dapat dipenuhi. Penilaian-penilaian ini membantu memastikan bahwa apa pun yang dibangun tidak akan runtuh dalam kondisi operasional normal atau menimbulkan masalah yang tidak perlu bagi komunitas sekitar di masa mendatang.

Mengetahui bagaimana bahan-bahan berperilaku di bawah tekanan dan apa yang terjadi pada distribusi beban membuat perbedaan besar dalam menjaga menara saluran transmisi tetap aman dan tahan lama. Saat membangun struktur-struktur ini, para insinyur perlu memperhatikan secara tepat bagaimana baja, beton, dan bahan lainnya merespons ketika dipengaruhi oleh gaya-gaya seperti angin kencang atau beban berat peralatan. Tidak ada yang ingin melihat menara runtuh karena seseorang melewatkan suatu perhitungan di suatu tempat. Mereka yang cerdas merencanakan sebelumnya untuk tekanan-tekanan ini sehingga mereka memilih bahan-bahan yang tepat sejak awal. Beberapa perusahaan bahkan menguji sampel dalam kondisi terkendali sebelum menetapkan desainnya. Pendekatan proaktif ini membantu menara-menaara tetap bertahan lebih baik terhadap segala sesuatu yang dilemparkan oleh Ibu Pertiwi selama puluhan tahun operasionalnya.

Ingeniur membutuhkan alat pemodelan yang baik jika mereka ingin mendapatkan hasil yang akurat saat mengerjakan desain mereka. Mereka sering menggunakan hal-hal seperti perangkat lunak CAD dan berbagai program simulasi yang memungkinkan mereka melihat seperti apa struktur sebenarnya dan memeriksa bagaimana struktur tersebut bertahan dalam berbagai kondisi. Nilai sebenarnya terletak pada kemampuan untuk mengidentifikasi masalah sejak dini dan menyesuaikan desain sebelum ada yang mulai membangun sesuatu secara fisik. Pendekatan ini menghemat waktu dan uang sekaligus menjaga keselamatan semua pihak selama konstruksi. Kebanyakan proyek modern sangat bergantung pada alat digital ini karena memang masuk akal dari segi efisiensi maupun untuk memenuhi standar rekayasa saat ini.

Tantangan dalam Menara saluran transmisi Desain

Menara saluran transmisi desain menghadirkan banyak tantangan, terutama dalam hal memenuhi seluruh persyaratan regulasi. Mengikuti standar lokal maupun global sangat penting untuk menjaga struktur tetap aman, stabil, dan tahan lama seiring waktu. Aturan tersebut tidak hanya memengaruhi tampilan menara di atas kertas, tetapi juga menentukan bahan apa yang digunakan dan bagaimana proses pembangunan dilakukan. Insinyur menghadapi pengawasan ketat sepanjang setiap tahap, mulai dari perencanaan hingga masa pensiun, karena regulator menginginkan kepatuhan yang ketat sepanjang waktu.

Dalam merancang struktur, insinyur menghadapi tantangan tambahan karena kondisi lokasi setempat. Karakteristik medan dan sifat tanah sangat berpengaruh terhadap stabilitas bangunan. Bayangkan saja: jika ada tanah lunak atau tanah beku di bawahnya, desain biasa sama sekali tidak akan berfungsi. Karena itulah kita melihat pendekatan khusus diperlukan di tempat-tempat di mana fondasi normal akan gagal total. Ambil contoh daerah rawa atau zona permafrost. Lingkungan seperti ini membutuhkan solusi yang benar-benar berbeda agar menara tidak roboh ketika tanah di bawahnya bergerak. Para insinyur telah mengembangkan beberapa solusi sementara yang cerdas di tempat seperti Siberia, di mana metode tradisional sama sekali tidak mampu bertahan menghadapi kondisi ekstrem.

Menara saluran transmisi harus mampu bertahan menghadapi berbagai bencana alam dan cuaca buruk. Dalam mendesain menara tersebut, para insinyur harus mempertimbangkan hal-hal seperti gempa bumi, badai besar, atau angin kencang yang bisa menyebabkan masalah serius jika tidak ditangani dengan baik. Agar struktur ini lebih tahan lama dan mampu mengatasi kondisi keras, biasanya bagian tertentu diperkuat, dipilih bahan bangunan yang lebih kuat, serta diterapkan lapisan khusus yang tahan terhadap kerusakan akibat cuaca. Pendekatan-pendekatan ini membantu memastikan jaringan listrik tetap utuh meskipun alam menghadirkan tantangan terberatnya.

Tren Masa Depan dalam Desain Menara

Menara saluran transmisi kini mendapatkan penyegaran yang ramah lingkungan. Banyak insinyur yang bekerja pada proyek jaringan listrik mulai mencari alternatif pengganti struktur baja konvensional yang sangat merugikan lingkungan. Jalan-jalan melalui lokasi konstruksi infrastruktur listrik modern, dan besar kemungkinan mereka sudah menggunakan bahan seperti paduan logam daur ulang atau campuran komposit baru yang tahan lama tanpa korosi. Bahan-bahan ini mengurangi emisi karbon selama proses produksinya, sekaligus tetap kuat menghadapi kondisi cuaca yang keras. Yang menarik adalah bagaimana tren ini bermakna baik dari segi lingkungan maupun ekonomi. Perusahaan-perusahaan menemukan bahwa menara yang dibangun dengan bahan berkelanjutan cenderung membutuhkan sedikit perawatan seiring waktu, sehingga menghemat biaya dalam jangka panjang meskipun investasi awalnya lebih tinggi.

Kami melihat ada hal menarik yang terjadi belakangan ini dalam pembangunan menara, yaitu teknologi pintar mulai merambah ke berbagai lokasi konstruksi. Kini sistem pemantauan canggih mulai diterapkan sehingga memungkinkan para insinyur untuk terus memantau kondisi menara secara real-time, sehingga masalah bisa diperbaiki sebelum menjadi masalah besar dan efisiensi keseluruhan meningkat. Menara pintar terbaru dilengkapi dengan berbagai macam sensor yang terhubung ke internet, mampu mendeteksi masalah struktural atau kemungkinan gangguan. Hal ini membuat menara menjadi jauh lebih andal dalam jangka panjang dan menghemat biaya perawatan di masa depan, meskipun biaya pemasangan awalnya sedikit lebih tinggi.

Inovasi desain telah menjadi faktor utama dalam cara menara dibangun saat ini. Insinyur kini sangat mengandalkan alat-alat seperti perangkat lunak CAD dan berbagai program simulasi untuk memperbaiki detail struktural sambil menjaga biaya tetap rendah. Dengan metode baru ini, mereka dapat mengidentifikasi titik-titik lemah potensial dalam struktur jauh sebelum konstruksi dimulai, yang berarti lebih sedikit kejutan selama pembangunan dan pengurangan bahan yang terbuang. Hasilnya? Menara yang bisa berdiri lebih tinggi, lebih tahan lama, dan tidak terlalu membebani anggaran.

FAQ

Apa tujuan utama menara jalur transmisi?

Menara jalur transmisi dirancang untuk mendukung saluran listrik udara tegangan tinggi, memfasilitasi distribusi listrik yang aman dan efisien dalam jarak jauh.

Jenis bahan apa saja yang digunakan di menara jalur transmisi?

Bahan-bahan yang umum digunakan termasuk baja, yang dikenal karena kekuatan dan biaya yang efektif, dan aluminium, yang menawarkan alternatif ringan dan tahan korosi.

Bagaimana faktor lingkungan mempengaruhi desain menara jalur transmisi?

Kondisi lingkungan seperti angin, fluktuasi suhu, kondisi tanah, dan aktivitas seismik mempengaruhi desain struktural, jenis fondasi, dan pilihan material untuk memastikan stabilitas dan keselamatan.

Apa pentingnya teknologi cerdas dalam desain menara masa depan?

Teknologi cerdas, melalui sensor dan konektivitas, memungkinkan pemantauan kondisi menara secara real-time, meningkatkan keandalan, efisiensi pemeliharaan, dan mengurangi biaya operasional.