The Importance of Environmental Factors in Power Towers

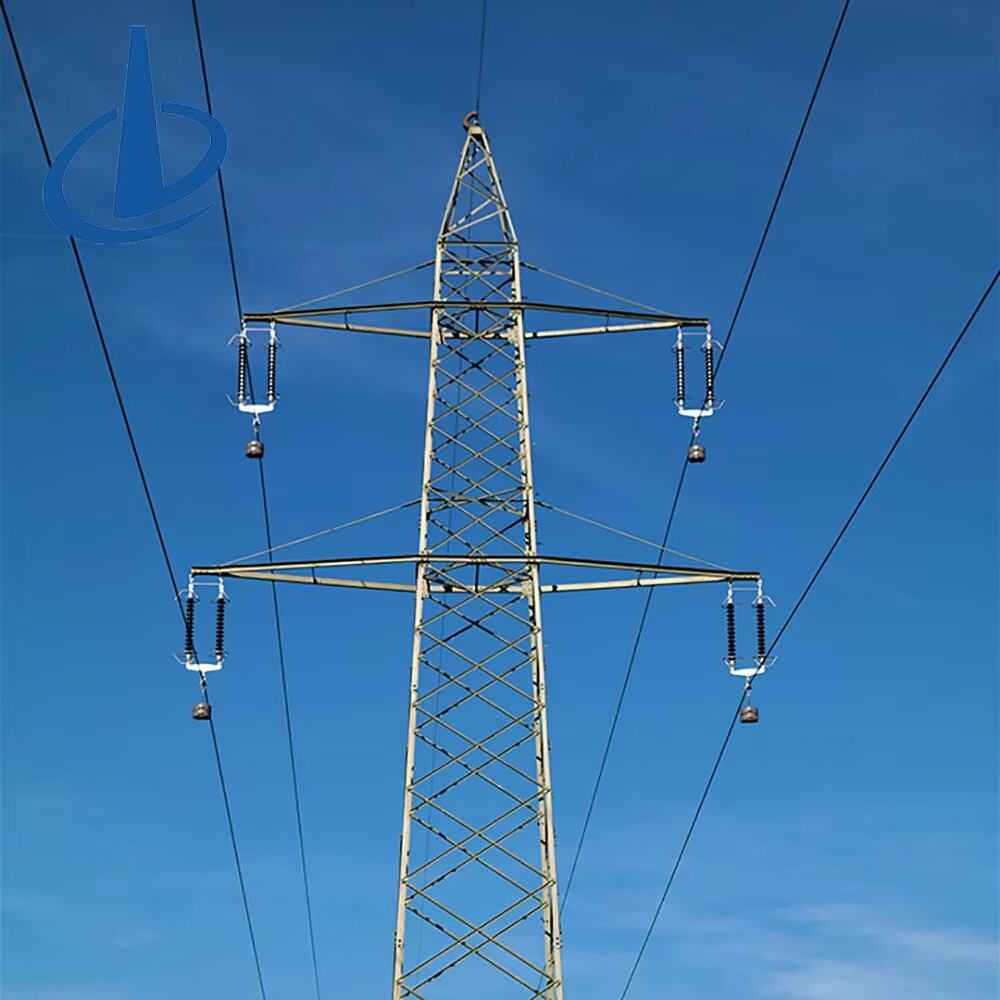

Power Towers are essential infrastructure for transmitting high-voltage electricity across cities, towns, and remote regions. They are designed to endure decades of use, but their actual lifespan is strongly influenced by the environmental conditions they face. From high winds to coastal humidity, the external environment shapes how well these structures can function and how often they require maintenance.

Why do some Power Towers last over 70 years while others show signs of fatigue much earlier? The answer lies in the way weather, temperature, and terrain interact with steel, concrete, and insulation materials. Corrosion, metal fatigue, foundation erosion, and conductor strain are all issues that arise from external conditions.

Understanding the link between environment and durability is crucial for designing stronger Power Towers and extending their operational life. With rising energy demands and global climate changes, addressing these environmental challenges becomes more important than ever.

Climatic Influences on Power Towers

Effects of High Wind and Storms

Power Towers are often exposed to powerful winds, hurricanes, and typhoons. When extreme wind forces push against their structures, vibrations and oscillations can gradually weaken joints and bolts. Over time, this can reduce structural integrity and shorten the lifespan of the towers.

To withstand such conditions, towers are engineered with lattice frameworks or guyed supports to distribute stress. Yet, without regular inspections after storms, hidden damages can accumulate, leading to costly repairs or replacements.

Influence of Temperature Extremes

Temperature fluctuations between scorching summers and freezing winters create thermal expansion and contraction in steel and concrete. This constant movement weakens materials, increases brittleness, and accelerates wear on insulators.

Power Towers in deserts face heat stress, while those in polar climates endure frost damage. Protective coatings and specialized alloys are therefore crucial in extending tower longevity under these extremes.

Environmental Degradation and Corrosion

Humidity and Coastal Salt Exposure

In coastal areas, Power Towers are exposed to salty air that accelerates corrosion. The combination of humidity and salt forms rust, which can spread quickly across steel components. Without anti-corrosion treatments, these towers can deteriorate far faster than those in drier inland regions.

Protective galvanization and routine repainting are essential defenses. Some towers are even fitted with specialized coatings designed to resist saltwater corrosion, ensuring decades of reliable operation.

Acid Rain and Industrial Pollution

Acid rain, caused by industrial emissions, can weaken the steel and concrete foundations of Power Towers. Polluted environments introduce chemical reactions that eat away at protective coatings, exposing raw materials to further damage.

In industrial zones, regular cleaning, monitoring, and applying protective barriers are necessary steps to slow degradation. These preventive measures play a vital role in ensuring tower durability.

Terrain and Soil Challenges

Mountainous and Rocky Areas

Building Power Towers in mountainous regions requires foundations anchored into rocky terrain. While rock provides stability, shifting geological conditions, landslides, and earthquakes can compromise the base.

The challenge lies in reinforcing the foundations and designing flexible structures that can absorb seismic movements. Engineering solutions in such regions directly influence how long the towers remain functional.

Wetlands and Flood-Prone Regions

In swampy or flood-prone areas, soil erosion is a significant risk. Foundations may weaken as water washes away support, creating instability in Power Towers. In such environments, deep pile foundations or elevated tower bases are often required.

Regular ground monitoring and water drainage systems can extend the operational life of these towers in challenging terrain.

Biological and Natural Impacts

Vegetation Growth and Wildlife Interactions

Vegetation around Power Towers can trap moisture, increasing rust risks. Roots from large trees may also weaken foundations. Additionally, nesting birds and climbing wildlife can damage insulators and conductors, leading to outages and physical strain on the structure.

Maintaining vegetation control and installing protective barriers reduces biological risks. These small measures play a major role in ensuring tower safety and long-term service.

Seismic and Geological Factors

Power Towers in earthquake-prone regions face sudden shocks that can bend or fracture steel supports. Even minor tremors, if repeated over years, can reduce resilience.

Design modifications such as base isolation systems or flexible joints are essential in such regions. They allow towers to absorb shocks while continuing to function.

Maintenance and Monitoring for Longer Lifespan

Routine Inspection and Preventive Care

How can operators ensure Power Towers last longer despite environmental threats? Regular inspections are the first step. Identifying corrosion, cracks, or misalignments early prevents small issues from becoming major structural failures.

Using drones, sensors, and thermal imaging, maintenance teams now inspect towers with greater accuracy. These technologies make preventive care more effective and less costly.

Upgrading Materials and Coatings

Modern materials provide stronger protection against environmental stress. Advanced steel alloys resist rust, while innovative coatings prevent moisture penetration.

Retrofitting older Power Towers with these upgrades ensures they can continue operating even in harsh conditions. This proactive approach often saves money compared to full replacements.

Innovations in Power Tower Design

Smart Monitoring Technologies

Today, Power Towers are being equipped with smart sensors that monitor vibrations, temperature changes, and stress in real time. These systems allow operators to predict failures before they happen.

By integrating digital tools, utilities can maximize tower lifespans while reducing risks of sudden outages. This innovation represents the future of power infrastructure.

Sustainable and Eco-Friendly Designs

As sustainability becomes a global priority, Power Towers are being designed to reduce environmental impact. Compact monopoles are replacing wide lattice structures in cities, while corrosion-resistant designs are deployed in coastal regions.

These eco-conscious designs not only extend lifespan but also align with environmental protection goals.

Economic and Strategic Importance

Cost of Replacement Versus Maintenance

Replacing Power Towers requires significant investment. By focusing on maintenance and environmental adaptation, operators save millions over decades. Preventive care and smart design choices always outweigh the costs of premature replacement.

Well-maintained towers also reduce outages, preventing economic losses from power interruptions. This makes proactive management not just a technical choice but a financial strategy.

Ensuring Grid Reliability and Stability

Reliable Power Towers ensure consistent electricity transmission across regions. When environmental conditions are properly managed, towers remain stable for decades, supporting national power security.

This long-term stability makes them a cornerstone of modern energy systems and highlights the importance of adapting to environmental challenges.

FAQ

What materials make Power Towers more resistant to environmental damage

Galvanized steel, weather-resistant alloys, and reinforced concrete are commonly used to resist corrosion, temperature stress, and soil erosion. Protective coatings also play a major role.

How often should Power Towers be inspected

In general, Power Towers should be inspected at least once a year. In coastal, industrial, or high-risk regions, more frequent inspections are recommended.

Do environmental factors affect all Power Towers equally

No, environmental impacts vary depending on location. Towers in deserts face heat damage, while those in coastal zones are more vulnerable to corrosion. Each environment requires unique solutions.

Can modern technology extend the lifespan of Power Towers

Yes, smart sensors, advanced coatings, and upgraded materials all significantly extend tower lifespans, reducing the need for costly replacements.

Table of Contents

- The Importance of Environmental Factors in Power Towers

- Climatic Influences on Power Towers

- Environmental Degradation and Corrosion

- Terrain and Soil Challenges

- Biological and Natural Impacts

- Maintenance and Monitoring for Longer Lifespan

- Innovations in Power Tower Design

- Economic and Strategic Importance

- FAQ