Vrozená síla a odolnost ocelových konstrukcí

Vynikající poměr síly k hmotnosti

Ocel má úžasnou pevnost v poměru ke své hmotnosti, která výrazně překonává beton i dřevo, a proto se stavebníci stále vrací zpět k jejímu použití ve svých projektech. Nižší hmotnost ocelových konstrukcí znamená, že inženýři mohou navrhovat konstrukce, které kladou menší nároky na ostatní části stavby. Stačí pomyslet na ty vysoké rozhlasové věže nebo sloupy elektrického vedení, které dnes všude vidíme. Ty vydrží proto, že jsou postavené lehce, ale zároveň silně. Pokud stavby využívají tuto vlastnost, skutečně ušetří peníze například na hlubokých základech nebo dodatečných podepíracích systémech. A řekněme si upřímně, úspora nákladů na materiálech a zároveň solidní výsledek činí ocel chytrou volbou pro rozsáhlé stavební projekty, kde záleží nejen na kvalitě, ale také na rozpočtu.

Odolnost vůči environmentální degradaci

Zinkování oceli zajišťuje mnohem lepší odolnost proti poškození způsobenému prostředím. Výzkumy ukazují, že pokud ocel dostane tento ochranný povlak, může vydržet o 50 až dokonce 100 let déle, což je zvlášť důležité pro konstrukce v blízkosti slané vody, kde se koroze urychluje. Peníze ušetřené na opravách se v průběhu desetiletí daří kumulovat, protože není třeba provádět neustálé údržby. Ocel si zachovává sílu proti rezavění a špatnému počasí, což pomáhá učinit budovy a infrastrukturu dlouhodobě udržitelnějšími. Proto se právě u mnoha moderních staveb spoléhá na zinek potaženou ocel například pro 5G komunikační věže a mobilní sítě po celé zemi. Tyto konstrukce potřebují materiály, které neztrácejí rychle své vlastnosti a zaručují tak jejich správné fungování po několik generací.

Dlouhodobá strukturální integrity

Ocelové konstrukce si po mnoho let udržují svou pevnost a odolnost, a to i za nepříznivých povětrnostních podmínek či působení jiních vnějších vlivů. Studie ukazují, že se ocelové konstrukce oproti jiným materiálům prakticky neopotřebovávají, a jsou proto ideální pro využití například v komunikačních věžích nebo velkých mostech po celé zemi. Pravidelné prohlídky pomáhají udržovat tuto odolnost na vysoké úrovni. Většina inženýrů doporučuje dvakrát ročně provádět vizuální inspekce a případně i základní testování nosných částí u ocelových konstrukcí, které jsou vystaveny vysokému zatížení. Důsledné dodržování těchto údržbových postupů nejenže prodlužuje životnost těchto staveb, ale také zvyšuje bezpečnost obyvatelstva během extrémních událostí, jako jsou bouřky nebo zemětřesení, a zajišťuje tak, že naše kritická infrastruktura zůstane zachována tam, kde je to nejpotřebnější.

Odolnost vůči požáru: Jak ocel zvyšuje bezpečnost budov

Nehořlavé vlastnosti oceli

Ocel neshoří, což dává stavbám z ní postaveným velkou výhodu z hlediska požární bezpečnosti. Opakované požární zkoušky prokázaly, že stavby s ocelovou konstrukcí jsou v případě požáru mnohem bezpečnější než ty z jiných materiálů, protože ocel prostě nehoří. Když vypukne oheň, ocelové konstrukce vydrží mnohem déle a zpomalí kolaps budovy. Tento časový prostor je klíčový pro evakuaci, udržuje lidi v bezpečí a zachraňuje životy. O tomto faktu je odborníci ve výstavbě dobře informováni, a proto zůstává ocel oblíbeným materiálem pro komerční stavby, kde musí být požární normy naprosto spolehlivé.

Role intumescensích nátěrů

Intumescenční nátěry zásadně zlepšují požární odolnost ocelových konstrukcí. Při vystavení teplu se tyto speciální nátěry skutečně rozšiřují a vytvářejí ochrannou kůru, která chrání ocelové konstrukce pod nimi před přehřátím. Odborníci na požární bezpečnost potvrzují, že tato technologie přináší reálné výsledky. Budovy opatřené těmito nátěry odolávají intenzivnímu požáru mnohem lépe než ty, které je nemají. Zlepšené bezpečnostní hodnocení znamená, že budovy déle odolávají při mimořádných událostech, což lidem poskytuje více času na bezpečný únik a hasičům více času na správné zvládnutí zásahu. Mnoho stavebních projektů nyní zahrnuje tyto nátěry jako standardní postup, protože se osvědčily ve skutečných situacích.

Případ Studie: Bezpečnost před požárem na zařízeních nafta a plyn

Analýza událostí při požáru vrtací plošiny z minulého roku ukazuje, jakou má ocelová konstrukce výhodu z hlediska požární bezpečnosti a připravenosti na mimořádné události. Když se objevily plameny, vlastnosti oceli umožnily záchranářům rychle zasáhnout a přesunout osoby i zařízení do bezpečnějších oblastí s minimálním zpožděním. Z toho vyplývá, že ocel není pouze silná za normálních okolností, ale zůstává spolehlivá i za extrémních teplot. Zařízení v celém ropném a plynárenském sektoru si této výhody začínají všímat. Zjistily, že jejich záchranné týmy ušetří drahocenné minuty díky tomu, že ocelová konstrukce odolává velmi dobře. To má velký význam, protože právě tyto minuty mohou znamenat rozdíl mezi malými škodami a katastrofou, která ohrožuje jak pracovníky, tak drahé vybavení.

Seismická výkonnost ocelových konstrukcí

Duktilita a disipace energie

Tvárnost oceli znamená, že dokáže dobře pohltit seizmickou energii, což pomáhá snižovat poškození při zemětřeseních. Tento jev je podložen výzkumem, který ukazuje, že budovy postavené z ocelových konstrukcí obecně odolávají otřesům mnohem lépe než konstrukce z jiných materiálů, protože se ohebně deformují místo toho, aby se lámy. Při pohledu na skutečné testy těchto konstrukcí zjišťujeme, že jejich pružnost skutečně rozptyluje energii zemětřesení, čímž celkově snižuje závažnost poškození. Šrouby používané pro spojování částí ocelových konstrukcí mají rovněž velmi důležitou úlohu při pohlcování energie. Pokud jsou tyto spoje správně navržené, umožňují určitým částem konstrukce dostatečný pohyb, který zabrání úplnému kolapsu a udrží celou budovu stojící i po silných otřesech. Díky tomu zůstává ocel oblíbeným materiálem pro výstavbu budov v oblastech s vysokým rizikem zemětřesení, kde je bezpečnost nejdůležitější.

Přizpůsobitelnost pro seizmickou rekonstrukci

Pružnost oceli opravdu září, pokud jde o aktualizaci starých budov tak, aby odpovídaly současným zemětřesným normám. Budovy postavené v době, kdy nebyla seizmická rizika na radaru všech, mohou být dnes díky ocelovým úpravám výrazně bezpečnější. Podívejte se například na to, co se stalo v San Francisku po zemětřesení Loma Prieta – mnoho historických objektů díky ocelovému posílení získalo druhou šanci. Ocelové práce obvykle zahrnují přidání věcí jako diagonální vzpěry nebo momentové konstrukce, věci, které se dají sestavit poměrně rychle ve srovnání s náročnějším procesem potřebným pro opravy betonu. Pro majitele nemovitostí, kteří chtějí, aby jejich budovy splňovaly platné předpisy, aniž by museli všechno bourat, zůstává ocel nejvhodnějším materiálem pro poskytnutí reálné šance starším objektům přežít budoucí otřesy.

Ocelové rámcování v oblastech ohrožených zemětřesením

Oblasti, které často zasahuje zemětřesení, mají velké výhody při použití ocelových konstrukčních systémů v projektech výstavby. Důkazy mluví samy za sebe, jakmile se podíváme na chování budov během skutečných zemětřesení v různých oblastech světa. Ocelové konstrukce vynikají tím, že zvládnou extrémní zatížení a zároveň splňují přísné stavební předpisy navržené zvlášť pro přípravu na katastrofy. Co činí ocel tak účinnou? Kombinuje výjimečnou sílu s dostatečnou pružností, aby pohltila seizmické vlny, aniž by praskala nebo se během tlaku zhroutila. Inženýři považují tento vyvážený poměr za zvlášť cenný v místech jako Japonsko nebo Kalifornie, kde jsou otřesy běžným jevem. Volbou ocelových konstrukcí architekti nechrání pouze majetek, ale doslova zachraňují životy, protože udržují lidi v bezpečí během seizmických mimořádných událostí. Proto mnohé moderní projekty ve vysoce siesmicky aktivních oblastech nyní standardně využívají těchto odolných ocelových kostru, a ne jako volitelné vylepšení.

Dodržování bezpečnostních standardů a stavebních předpisů

Splňování požadavků NFPA a ASTM

Ocelové konstrukce musí dodržovat přísná bezpečnostní pravidla stanovená organizacemi, jako je National Fire Protection Association (NFPA) a American Society for Testing and Materials (ASTM). Tato doporučení mají velký význam pro bezpečnost budov proti požárům a zajištění jejich dlouhodobé odolnosti. Bezpečnostní kontroly a získání stavebního povolení často závisí také na splnění těchto požadavků. NFPA a ASTM ve skutečnosti stanovují podrobné testy, které ověřují, zda stavební materiály odpovídají požadované kvalitě. Pokud stavitelé a architekti dodržují tato pravidla, v podstatě sledují osvědčené postupy průmyslu při tvorbě svých návrhů. To nejen zvyšuje bezpečnost budov, ale také pomáhá prodloužit jejich životnost před potřebou rozsáhlých oprav nebo výměny.

Role třetích stran při inspekci

Provádění nezávislých kontrol pomáhá zajistit, aby budovy splňovaly všechny nezbytné předpisy. Tyto kontroly fungují jako důležité kontrolní body během výstavby, kdy všichni zúčastnění vědí, že někdo sleduje průběh prací. Nezávislí inspektoři často objeví problémy, které by mohly výrazně oslabit konstrukci, pokud by zůstaly bez nápravy. Díky včasnému nalezení těchto problémů je možné je napravit dříve, než všechno bude trvale zabudováno. Celý záměr spočívá v tom, aby se na věc podíval někdo, kdo nemá zájem hájit zájmy stavebníka nebo developerů. Tento druh externí kontroly celkově zvyšuje bezpečnost budov a poskytuje klid majitelům nemovitostí, stejně jako všem, kteří budou prostory v budoucnu využívat.

Globální regulační trendy v ocelovém stavitelství

Ocel se v poslední době ve světě stává stále populárnější v oblasti stavebnictví, protože nabízí lepší bezpečnostní vlastnosti a environmentální výhody ve srovnání s tradičními materiály. Několik zemí již začalo přehodnocovat své stavební předpisy, aby zohlednily tyto výhody, což mnozí považují za milník v moderních stavebních metodách, kde je hlavní pozornost zaměřena na bezpečnost. Zprávy od předních odborných skupin ukazují, že městští developerské firmy se stále častěji rozhodují pro ocel při plánování nových infrastrukturních projektů. Uvědomují si nejen vysokou pevnost tohoto materiálu, ale také jeho odolnost vůči různým namáháním v průběhu času, což ji činí zvláště vhodnou pro stavby, které musí odolávat extrémním podmínkám.

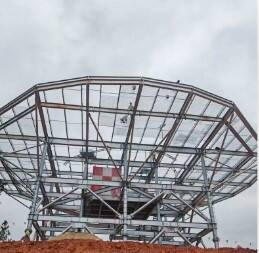

Ocel v kritické infrastruktuře: Vysílací věže a vedení elektřiny

Bezpečnost ve věžích 5G a anténových konstrukcích

Ocel je naprosto zásadní pro zajištění bezpečnosti a efektivity 5G věží a anténních konstrukcí. To, co činí ocel v tomto případě tak cennou, je její pozoruhodná pevnost v kombinaci s výbornou tvarovatelností, která umožňuje přizpůsobení různým návrhům věží. Studie ukazují, že ocel vyniká zejména odolností proti větrnému zatížení, což je zvlášť důležité ve městech, kde musí zůstat budovy stabilní i v případě velkých výšek. Ocelové konstrukce si již mnohokrát dokázaly svou spolehlivost během bouří a extrémních povětrnostních událostí. Udržují mobilní sítě v chodu i tehdy, když příroda způsobí největší nepokoje, což znamená méně přerušených hovorů a lepší internetové připojení pro všechny, kdo v těchto oblastech žijí nebo pracují.

Odolnost elektrické přenosové věže

Ocel tvoří základ elektrických přenosových věží, protože nabízí právě správnou kombinaci pevnosti a odolnosti potřebné k vyrovnání všeho, co na ně může příroda vrhnout, od zuřivých bouří až po těžké sněhové zatížení. Když inženýři hodnotí, jak odolná musí být naše infrastruktura, stále se obrací k oceli jako k materiálu, který udržuje tyto vysoké konstrukce stojící za všech drtivých podmínek. To má velký význam, protože potřebujeme, aby elektřina spolehlivě proudila do nemocnic, záchranných služeb a dalších klíčových zařízení během nepříznivých povětrnostních událostí. Bez silných materiálů, jako je ocel, které drží vše pohromadě, by výpadky elektrického proudu byly mnohem častější a rušivější po celé zemi, a to nejen v běžném životě, ale také by způsobovaly vážné finanční ztráty pro firmy i celá města.

Případová studie: Odolnost proti výbuchům na průmyslových lokalitách

Když hrozí riziko výbuchu v průmyslových zařízeních, ocelové konstrukce skutečně obstojí. Výzkum z reálných událostí ukazuje, že ocelové konstrukce často překračují požadavky spolkových předpisů na ochranu proti výbuchům a chrání tak důležité zařízení i provoz. Způsob, jakým ocel odolává v těchto nebezpečných situacích, z ní činí téměř nezbytný prvek pro místa, kde by mohlo dojít k explozím. To je důvod, proč potřebují továrny a provozy tento druh pevného základu, aby mohly nadále provozovat svou činnost a zároveň chránit pracovníky i budovy. Ocel byla opakovaně testována v reálných podmínkách a neustále se potvrzuje, že je nejlepší volbou, pokud jde o bezpečnost lidí i majetku.

Inovace v technologii bezpečnosti oceli

Systémy reálného časového monitorování struktur

Nejnovější pokroky v oblasti technologií reálného monitorování mění způsob, jakým ověřujeme integritu budov, a umožňují tak zjistit problémy dlouho předtím, než by se mohly stát vážnými bezpečnostními riziky. Když inženýři instalují tyto malé IoT senzory napříč mosty nebo vysokými budovami, dostávají průběžné aktualizace o tom, jak konstrukce odolává namáhání. Představte si to jako kdyby vám lékař neustále kontroloval životní funkce a hledal příznaky upozorňující na problémy. Tento druh monitorování znamená, že servisní týmy nemusí čekat, až něco přestane fungovat, aby to opravily. Místo toho mohou vyrazit hned, jakmile systém vyhodnotí, že došlo k problému, což šetří náklady a, což je nejdůležitější, předchází nehodám. Stavební firmy začínají tento přístup považovat za nezbytný, nikoli jen za další drahý hračku.

Vysokostranné ocelové slitiny

Vysokopevné ocelové slitiny mají v současnosti pro stavební materiály poměrně velký význam. Nabízejí lepší schopnost nést zatížení a mnohem lépe odolávají nárazům než tradiční materiály. To, co tyto speciální slitiny činí tak užitečnými, je jejich schopnost udržet si strukturu i za extrémního namáhání, aniž by došlo k jejímu poškození. To řeší mnoho problémů, se kterými se dnes setkávají stavitelé při výstavbě objektů, které musí vydržet náročné podmínky. Studie opakovaně prokázaly, že budovy postavené z těchto pokročilých ocelí skutečně vydrží větší tíhu a tlak, než se na nich objeví první známky opotřebení. Proto se tyto oceli stále častěji používají v mostech, mrakodrapech a jiných infrastrukturních projektech, kde je na trvání materiálu kladen zvláštní důraz. Ocelářský průmysl neustále nachází nové způsoby, jak tyto materiály dále posilovat, a zároveň udržovat jejich nákladovou efektivitu pro široké uplatnění v různých stavebních oborech.

Udržitelné řešení protipožární ochrany

Nové ekologické možnosti protipožární ochrany cílí na omezení škod na životním prostředí, přičemž stále zajišťují bezpečnost budov před plameny. Tato řešení kombinují přírodní ingredience s několika chytrými chemickými přísadami. Výzkum ukazuje, že mnoho těchto ekologických alternativ ve skutečnosti funguje stejně dobře jako materiály používané desítky let, což pomáhá firmám splňovat přísné ekologické stavební předpisy. Stavební průmysl začíná pochopit, že už nemusí volit mezi ekologickým přístupem a bezpečností. Stavitelé nyní mohou vytvářet konstrukce, které chrání lidi při požárech a zároveň zanechávají menší uhlíkovou stopu, což má v dnešním trhu smysl jak z hlediska etického, tak i ekonomického.

Často kladené otázky

Jaké jsou výhody poměru síly ku hmotnosti oceli?

Vynikající poměr síly ku hmotnosti oceli umožňuje lehčí konstrukce, snižující strukturní zátěž a minimalizující náklady spojené s fundacemi, což ji činí nákladově účinnou pro velké projekty.

Jak zvýšuje galvanizace odolnost oceli?

Galvanizace významně prodlužuje životnost oceli, zejména v pobřežních oblastech, poskytováním vylepšené odolnosti proti korozi a snižováním údržbových nákladů během času.

Proč se ocel preferuje pro požární bezpečnost v stavebnictví?

Nenáplnivé vlastnosti oceli snižují šíření požáru, udržují integrity budovy déle během požárních událostí a poskytují klíčový čas pro evakuaci a zvyšují celkové bezpečnost.

Jakou roli hrají intumescentní nátěry v požární bezpečnosti oceli?

Intumescentní nátěry se rozšiřují při vysokých teplotách, tvoříce ochrannou vrstvu uhelnatého materiálu, která izoluje ocel a zvyšuje odolnost proti požáru a strukturální integritu během požárních incidentů.

Jak se ocel chová při zemětřeseních?

Dutelnost oceli umožňuje efektivní absorpci a dychtivání energie, minimalizuje škody způsobené zemětřesením deformací bez prasknutí a chrání strukturální integritu.

Obsah

- Vrozená síla a odolnost ocelových konstrukcí

- Odolnost vůči požáru: Jak ocel zvyšuje bezpečnost budov

- Seismická výkonnost ocelových konstrukcí

- Dodržování bezpečnostních standardů a stavebních předpisů

- Ocel v kritické infrastruktuře: Vysílací věže a vedení elektřiny

- Inovace v technologii bezpečnosti oceli

- Často kladené otázky