Понимание требований к безопасности при строительстве опор линий электропередачи

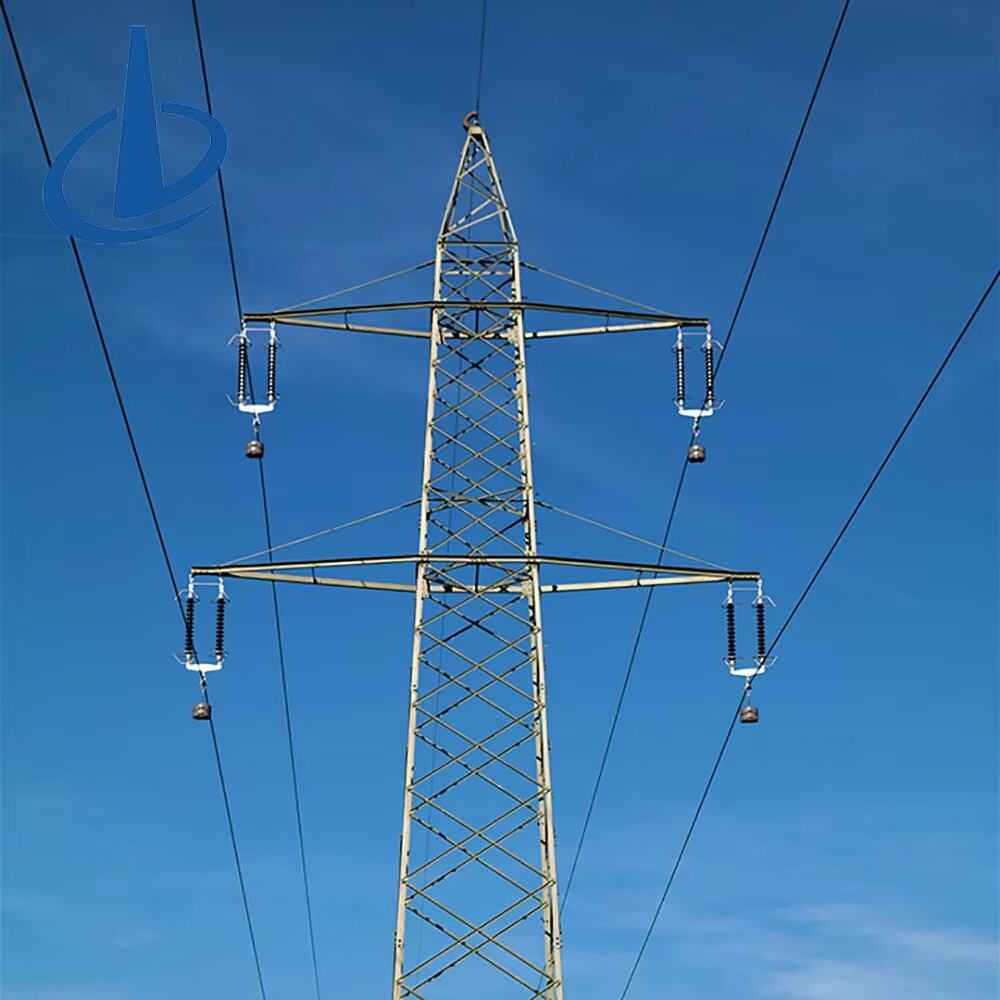

Опор линий электропередачи являются важнейшими элементами инфраструктуры в нашей электрической сети, однако их строительство требует строгого соблюдения комплексных стандартов безопасности. Эти высокие сооружения, которые могут достигать высоты более 200 футов, требуют тщательного соблюдения протоколов безопасности на каждом этапе — от первоначального проектирования до окончательного монтажа и дальнейшего технического обслуживания. Стандарты безопасности линий электропередач охватывают множество аспектов, включая конструктивную целостность, электробезопасность, защиту работников и экологические соображения.

Строительство и обслуживание опор линий электропередачи связано со сложными инженерными принципами и строгим соблюдением нормативных требований. Эти стандарты постоянно совершенствуются с целью внедрения новых технологий безопасности и реагирования на возникающие вызовы в сфере распределения электроэнергии. Понимание этих требований имеет важнейшее значение для энергетических компаний, строительных фирм и специалистов по безопасности, участвующих в проектах развития энергетической инфраструктуры.

Основные требования к конструкционной безопасности

Требования к фундаменту и основанию

Фундамент силовой башни служит её основной опорой и должен соответствовать конкретным критериям безопасности. Инженеры должны проводить тщательный анализ почвы и геологические изыскания, чтобы убедиться, что грунт способен выдержать вес башни и противостоять различным внешним воздействиям. Глубина фундамента обычно составляет от 10 до 15 футов ниже уровня земли в зависимости от состояния почвы и высоты башни.

Бетон, используемый в фундаментах силовых башен, должен иметь минимальную прочность на сжатие 4000 PSI и проходить регулярные испытания в процессе твердения. Основание должно включать армированные стальные элементы и быть рассчитанным на восприятие как вертикальных нагрузок, так и боковых усилий от ветра и других внешних факторов.

Технические характеристики материалов и грузоподъёмность

Стандарты безопасности опор линий электропередачи требуют использования высококачественной стали и других материалов, отвечающих конкретным требованиям по прочности. Эти материалы должны проходить строгие испытания и процедуры сертификации перед утверждением для использования в строительстве опор. Стальные компоненты обычно должны выдерживать предел прочности на растяжение до 65 000 фунтов на квадратный дюйм (PSI) и подвергаться защитной обработке от коррозии.

Расчёты грузоподъёмности должны учитывать постоянные нагрузки (вес самой опоры), временные нагрузки (рабочие и оборудование при обслуживании) и внешние нагрузки (ветер, гололёд и сейсмические воздействия). В эти расчёты закладываются коэффициенты запаса прочности, которые обычно требуют, чтобы конструкции выдерживали нагрузки, превышающие ожидаемые максимальные в 2,5–3 раза.

Электробезопасность

Системы изоляции и заземления

Правильная изоляция является основополагающим аспектом стандартов безопасности энергетических башен. Линии передачи высокого напряжения требуют определённых расстояний по охранной зоне и характеристик изоляторов в зависимости от уровня напряжения. Изоляторы должны соответствовать строгим стандартам качества материалов и проходить регулярные испытания для обеспечения их целостности.

Системы заземления защищают от ударов молнии и электрических неисправностей. Эти системы, как правило, включают несколько заземляющих стержней, кабели-проводники и соединения, сопротивление которых должно быть менее 10 Ом. Регулярное тестирование и обслуживание систем заземления являются обязательными для обеспечения их постоянной эффективности.

Управление электромагнитным полем

Стандарты безопасности устанавливают предельно допустимые уровни воздействия электромагнитного поля (ЭМП) как для работников, так и для населения. Конструкции башен должны предусматривать специальные зоны отступа и меры экранирования для минимизации воздействия ЭМП. Требуется регулярный контроль и документирование уровней ЭМП для обеспечения соблюдения безопасных пороговых значений.

Зоны защиты вокруг опор линий электропередачи должны быть четко обозначены и поддерживаться в зависимости от уровней напряжения и высоты опоры. Эти зоны, как правило, простираются от основания опоры наружу и требуют установки специальных знаков и ограничений доступа.

Требования к безопасности работников

Стандарты средств индивидуальной защиты

Работники, участвующие в строительстве и обслуживании опор линий электропередачи, должны использовать соответствующее индивидуальное защитное оборудование (СИЗ). К нему относится специальное снаряжение для подъема, диэлектрические перчатки, рассчитанные на определенные уровни напряжения, и системы защиты от падения, соответствующие требованиям OSHA или превышающие их.

Страховочные пояса должны проходить регулярную проверку и сертификацию, как правило, каждые шесть месяцев или после любого значительного воздействия. Работники должны проходить документированное обучение правильному использованию и обслуживанию СИЗ, а повторные курсы должны проводиться ежегодно.

Протоколы доступа и подъема

Строгое соблюдение протоколов регулирует доступ к вышкам и процедуры подъёма. К ним относятся обязательная система «партнёр» при выполнении работ на высоте, оценка погодных условий перед подъёмом, а также детальные планы реагирования на чрезвычайные ситуации. Снаряжение для подъёма должно соответствовать определённым показателям нагрузки и проходить регулярную проверку на безопасность.

На более высоких сооружениях через определённые интервалы, как правило, каждые 50 футов, должны быть установлены площадки для отдыха, способные выдерживать вес нескольких рабочих вместе с оборудованием. На всех рабочих местах должна быть readily available аварийная система спуска и оборудование для спасения.

Экологические и погодные факторы

Нормы ветровой нагрузки

При проектировании опорных башен необходимо учитывать максимальную скорость ветра, характерную для конкретного географического региона. При расчётах конструкций обычно применяются коэффициенты ветровой нагрузки, превышающие исторические максимумы скорости ветра на 25% или более. Регулярные структурные проверки обеспечивают постоянное соответствие требованиям устойчивости к ветровым нагрузкам.

В районах, подверженных ураганам, действуют особые требования, поскольку башни должны выдерживать устойчивый ветер со скоростью до 150 миль в час и выше. В таких районах могут потребоваться конструктивные изменения, включая дополнительные растяжки или усиленные основания.

Влияние льда и температуры

В регионах, склонных к образованию льда, стандарты безопасности энергетических башен требуют специальных конструктивных элементов для компенсации дополнительного веса и напряжения из-за накопления льда. В определённых климатических зонах могут быть обязательными системы антиобледенения и специальные покрытия.

Необходимо учитывать влияние температурных колебаний при выборе материалов и проектировании компенсационных швов. Как правило, стандарты требуют, чтобы материалы сохраняли структурную целостность в диапазоне температур от -40°F до 120°F.

Часто задаваемые вопросы

Как часто энергетические башни должны проходить проверку безопасности?

Вышки электропередачи должны проходить комплексные проверки безопасности не реже одного раза в год, а визуальные осмотры — ежеквартально. После экстремальных погодных явлений или любых инцидентов, которые могут повлиять на целостность конструкции, проводятся дополнительные обязательные проверки. Эти проверки должны выполняться сертифицированными специалистами и документироваться в соответствии с требованиями регулирующих органов.

Каковы минимальные требования к зазорам вокруг опор линий электропередачи?

Минимальные требования к зазорам зависят от уровня напряжения и высоты опоры. Обычно горизонтальный зазор должен составлять не менее 30 футов от центра опоры для стандартных линий электропередачи, а вертикальные зазоры могут варьироваться от 25 до 35 футов над уровнем земли. Для линий с более высоким напряжением эти расстояния увеличиваются и должны учитывать раскачивание проводников при ветровых нагрузках.

Какие сертификаты по технике безопасности требуются для рабочих, участвующих в строительстве опор линий электропередачи?

Работники должны иметь несколько сертификатов по технике безопасности, включая обучение по программе OSHA по защите от падений, сертификат по электробезопасности, соответствующий уровням напряжения, и сертификат на работу на высоте. Дополнительные требования могут включать обучение оказанию первой помощи и спасательным работам, сертификацию на право входа в ограниченные пространства и удостоверения на эксплуатацию конкретного оборудования. Эти сертификаты необходимо регулярно обновлять, а также проходить постоянное обучение для поддержания их действительности.