Förstå grunden för eldistributionsinfrastruktur

Elektriska stålar utgör grunden för våra moderna eldistributionsystem och står som tysta väktare som håller vår värld ansluten och upplyst. Dessa väsentliga konstruktioner för transporterar kraftledningar över stora avstånd och säkerställer att el når hem, företag och industrier effektivt. Utvecklingen av elstolpar har varit anmärkningsvärd, från enkla trästolpar till sofistikerade ingenjörsstrukturer utformade för att tåla olika miljöpåfrestningar samtidigt som de säkerställer pålitlig kraftöverföring.

Vanliga material använda vid konstruktion av elstolpar

Träelstolpar

Träelstolpar är fortfarande ett av de mest spridda alternativen i eldistributionssystem. De tillverkas vanligtvis av behandlad tall eller ceder och erbjuder naturliga isolerande egenskaper samt är relativt kostnadseffektiva. Behandlingsprocessen innebär att skyddande medel tränger djupt in i träet, vilket skyddar det mot förruttnelse, insekter och väderpåverkan. Med ordentlig underhåll kan träelstolpar hålla i 30–40 år.

Fördelarna med träelstolpar inkluderar deras förnybara natur, enkla installation och möjligheten att klättra upp på dem säkert av elnätsarbetare. De är särskilt lämpliga för landsbygdsområden och bostadsområden där estetiska aspekter är viktiga. Dock kräver de regelbundet underhåll och kan vara känsliga för extrema väderförhållanden.

Elektriska stångar av stål

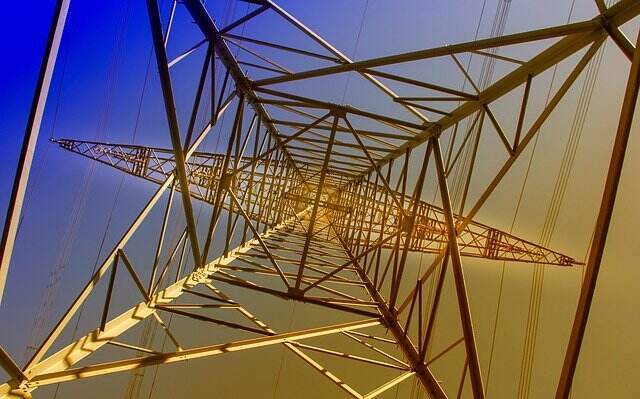

Stålelektriska stolpar representerar toppen av styrka och hållbarhet i kraftfördelningsinfrastruktur. Dessa stolpar är konstruerade för att hantera tunga laster och motstå extrema väderförhållanden. Konstruktion i galvaniserat stål ger utmärkt skydd mot korrosion, medan deras ihåliga design möjliggör inre kablage och montering av utrustning.

Modernaste stålelektriska stolpar finns i olika former och storlekar, från traditionella runda stolpar till polygonala design som erbjuder förbättrad strukturell integritet. De är idealiska för högspända ledningar och områden benägna för allvarliga väderhändelser. Även om den initiala kostnaden är högre än trä, gör ofta deras längre livslängd och minimala underhållskrav dem mer kostnadseffektiva på lång sikt.

Specialiserade elstolpdesigner

Betong elektriska poler

Betongelstolpar har blivit allt mer populära på grund av sin exceptionella hållbarhet och motståndskraft mot miljöpåverkan. Dessa stolpar är förstärkta med armeringsjärn och förspända för att förbättra deras bärförmåga. De är särskilt lämpliga för kustnära områden där saltvatten kan försämra andra material.

Tillverkningsprocessen för betongelstolpar möjliggör noggrann kvalitetskontroll och konsekventa specifikationer. De kan utformas för att hantera olika spänningsnivåer och utrustningskonfigurationer. Även om de är tyngre än andra alternativ, vilket gör installationen mer krävande, gör deras långa livslängd och minimala underhållsbehov dem till ett attraktivt val för elnätsföretag.

Kompositelstolpar

Som representerar den senaste innovationen inom stolpteknik kombinerar komposita elstolpar glasfiber, harpikser och andra avancerade material för att skapa lättviktiga men otroligt starka strukturer. Dessa stolpar erbjuder överlägsen resistens mot ruttnande, insekter och miljönedbrytning samtidigt som de ger utmärkta isoleringsegenskaper.

Kompositmaterialens mångsidighet möjliggör anpassade designlösningar som uppfyller specifika kraftrörsbehov. Dessa stolpar är särskilt värdefulla i områden med svårt tillgänglig terräng eller där viktbegränsningar gäller. Även om den initiala kostnaden är högre motiveras investeringen ofta av deras längre livslängd och minimala underhållsbehov.

Tillämpningar och användningsscenarier

Transformatorstationsspjut

Elstolpar för kraftledningar är konstruerade för att bära högspänd ström över långa avstånd. Dessa konstruktioner är vanligtvis högre och mer robusta än distributionsstolpar och når ofta höjder på 30 meter eller mer. Stål och betong är de föredragna materialen för dessa applikationer på grund av deras överlägsna hållfasthet och stabilitet.

Konstruktionen av stolpar för kraftledningar måste ta hänsyn till faktorer såsom ledarspänning, vindlast och isackumulering. De innehåller ofta specialiserade isolatorer och hårddiskar för att upprätthålla säkra avstånd och förhindra elektriska fel. Placeringen och avståndet mellan dessa stolpar kräver noggrann ingenjörsutformning för att optimera effektiviteten i kraftöverföringen.

Stolpar för distributionsnät

Elstolpar för distribution utgör den sista länken för att leverera el till slutanvändare. Dessa stolpar är vanligtvis kortare än transmissionsstolpar och bär ledningar med lägre spänning. De förekommer ofta i bostadsområden och kommersiella distrikt, där de bär transformatorer, gatubelysning och kommunikationsutrustning.

Valet av stolpmaterial för distributionsnät beror ofta på lokala förhållanden och elbolagens preferenser. Trästolpar är fortfarande populära i många områden, medan urbana miljöer ofta föredrar stål- eller betongstolpar på grund av deras hållbarhet och lägre underhållsbehov.

Underhåll och livscykelöverväganden

Inspektion och bedömning

Regelbunden besiktning av elstolpar är avgörande för att upprätthålla systemets tillförlitlighet och allmän säkerhet. Elbolag använder olika metoder, från visuella bedömningar till avancerade skanningstekniker, för att utvärdera stolparnas skick. Dessa inspektioner hjälper till att identifiera potentiella problem innan de leder till haverier.

Inspektionsfrekvensen och djupet varierar beroende på stolpmaterial, ålder och miljöförhållanden. Moderna övervakningssystem kan till och med inkludera sensorer som ger realtidsdata om stolpens strukturella integritet och prestanda.

Utbytes- och uppgraderingsstrategier

Att utveckla effektiva strategier för byte och uppgradering av stolpar är viktigt för elbolag. Faktorer såsom ålder, skick, lastkrav och föreskrivna standarder påverkar dessa beslut. En välplanerad strategi bidrar till optimal resursfördelning samtidigt som systemets tillförlitlighet bibehålls.

Moderna elnätsföretag implementerar ofta förutsägande underhållsprogram som använder dataanalys för att förutsäga livslängden på stolpar och planera utbyggnad. Detta proaktiva tillvägagångssätt hjälper till att förhindra oväntade haverier och förlänger infrastrukturens livslängd.

Vanliga frågor

Vad avgör livslängden på elstolpar?

Livslängden på elstolpar beror på flera faktorer, inklusive materialtyp, miljöförhållanden, underhållspraxis och belastningskrav. Trästolpar håller vanligtvis 30–40 år med ordentlig behandling, medan stål- och betongstolpar kan överstiga 50 år. Regelbundna besiktningar och underhåll kan avsevärt förlänga stolpens livslängd.

Hur väljer elnätsföretag rätt typ av elstolpe för specifika platser?

Elbolag tar hänsyn till flera faktorer vid val av elstolpar, inklusive lokala klimatförhållanden, jordart, lastkrav, tillgänglighet och kostnadsaspekter. De utvärderar också regleringskrav, miljöpåverkan och långsiktiga underhållsbehov för att fatta välgrundade beslut.

Vilka säkerhetsfunktioner ingår i moderna elstolpar?

Moderna elstolpar inkluderar olika säkerhetsfunktioner såsom klättersteg eller klättertappar, varningsskyltar, klätterskydd och korrekta jordningssystem. De är utformade med lämpliga avstånd för kraftledningar och innehåller ofta åtgärder för skydd av vilda djur. Avancerade material och beläggningssystem hjälper också till att förhindra försämring och bibehålla strukturell integritet.